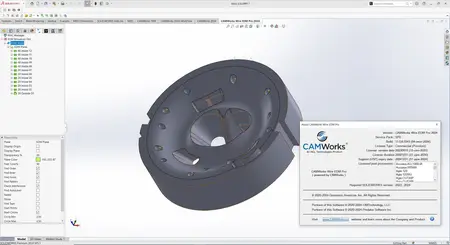

Free Download CAMWorks WireEDM Pro 2024 SP0 | 1.4 Gb

Languages Supported: English, Deutsch, Español, Čeština, 日本語

GeometricPLMis pleased to announce the availability ofCAMWorks WireEDM Pro 2024 SP0is has been designed and developed specifically for programming 2-axis through 4-axis Wire EDM CNC machines using feature-based technology, including automatic feature recognition and knowledge-based machining, to automate the Wire EDM programming process.

Owner:GeometricPLM

Product Name:CAMWorks WireEDM

Version:2024 SP0

Supported Architectures:x64

Website Home Page :www.camworks.com

Languages Supported:multilanguage

System Requirements:Windows *

Software Prerequisites:pre-installed SolidWorks 2023 or 2024

Size:1.4 Gb

New in CAMWorks WireEDM Pro 2024 SP0

5th Axis Rotary Indexing

Purpose:To provide the functionality of machining parts in multiple positions or setups within one program by using an additional rotary axis

Implementation:Rotary Indexing allows for more efficient machining, letting the user machine from multiple sides

of the part without needing to remove and set up the part multiple times.

User-defined NC Code File Output Options

Purpose:To provide functionality to allow users to define the name of the post processed output file

Implementation:Allowing the ability to define how and where output files should be saved gives the user more

control and flexibility in managing created programs.

Agie-Charmilles Uniqua Support

Purpose:To provide the functionality of defining many of the various settings available on the Agie-Charmilles Uniqua control by adding an additional Uniqua Settings page for operations

Implementation:The Uniqua control developed by GF Machining Solutions present the user with many settings that are not typically available. The Uniqua Settings page will allow users to set many of these control options with CAMWorks Wire EDM Pro, increasing the efficiency and allowing the programming to be done all at once before going to the machine.

Resolved CPRs in CAMWorks Wire EDM Pro 2024 SP0

1. CWE-861 CSR-25177 In CAMWorks Wire EDM Pro, the Agie Uniqa post processor only supports a single Glue stop. The ability to support multiple Glue stops. Needs to be provided.

2. CWE-860 CSR-25146 For the specific part, CAMWorks Wire EDM Pro does not allow the Leadin value to be greater than 0.07 Inches. This is observed even when the 'Auto Trim' option is disabled.

3. CWE-854 CSR-25082 In CAMWorks Wire EDM Pro, when open toolpaths are generated with Leadin/Leadout set to start point, those toolpaths will cut through the part.

4. CWE-828 -- Provide a File/Save dialog option that allows the users to assign the name to the post processed output file.

5. CWE-816 CSR-24196 In CAMWorks Wire EDM Pro, only the Feed moves are generated for On Contour' toolpath and no rapid moves get generated. However, the CAMWorks Wire EDM Pro Online Help mentions both the moves can be generated.

6. CWE-805 CSR-23945 When selecting the Cutting Condition Database in EDM Settings, if the machine type selected is a new Mitsubishi, then the file extensions should be *.MITSCC.

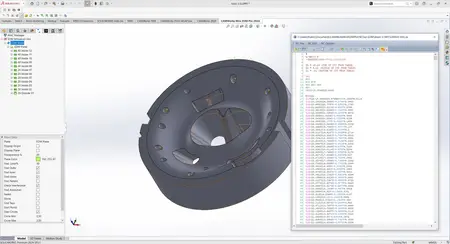

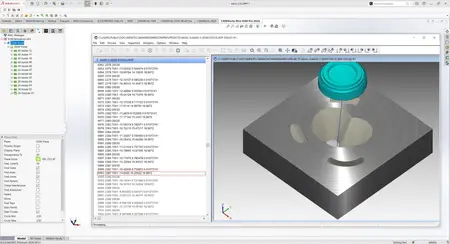

CAMWorks WireEDM Prois a newly introduced application in the CAMWorks suite of software products. It is a culmination of over 30 years of specialization in Wire EDM CAM technology. CAMWorks WireEDM Pro is seamlessly integrated to work as an Add-in within theSOLIDWORKS/CAMWorks Solids CADapplications. It is designed to automatically analyze a solid model, generate a machining plan for all the features (2 Axis, 2 Axis Taper, 4 Axis) and then post the G-Code with a single mouse click! It applies the cutting technology of your Wire EDM machine to the geometry of the solid model to be machined to generate the best possible G-code for your machine. This functionality allows you to take full advantage of all the latest cutting improvements in the field of Wire EDM technology. CAMWorks Wire EDM Pro will be an ideal choice for firms working with machining solid part models using WireEDM CAM technology.

CAMWorks WireEDM Demo

GeometricPLMby HCL Technologies a specialist in the domain of engineering solutions, services and technologies. Its portfolio of Global Engineering services, Product Lifecycle Management (PLM) solutions, Embedded System solutions, and Digital Technology solutions enables companies to formulate, implement, and execute global engineering and manufacturing strategies aimed at achieving greater efficiencies in the product realization lifecycle.

CAMWorks WireEDM Pro 2024 SP0 Win x64 Torrent Download , CAMWorks WireEDM Pro 2024 SP0 Win x64 Crack Download , CAMWorks WireEDM Pro 2024 SP0 Win x64 Patch Download , CAMWorks WireEDM Pro 2024 SP0 Win x64 Serial Keygen Download