Published 1/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 797.98 MB | Duration: 1h 34m

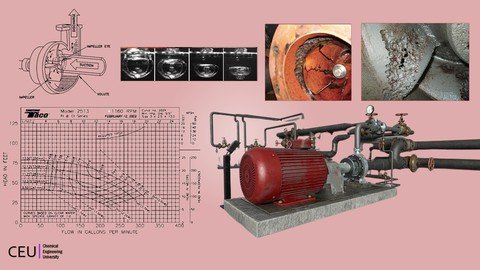

The Course for Development of Fundamental Knowledge on Pump Essentials and Sizing Parameters

Free Download What you'll learn

Pump Fundamentals

Centrifugal and Positive Displacement Pump Comparisons

Industrial Utilization of Various Pump Types

Pumps General Characterization

Parameters Affecting Pump Selection Procedure

Head, Flow Rate, Specific Speed

Shutoff Head

Power Requirements of Pump

NPSH, Risk of Cavitation

Pump Performance Curves

Pumps Operational Issues

Requirements

Fluid Flow Fundamentals is a must for understanding this course better. No further requirements other than that.

Description

Pump Unit Operation: Fundamentals and Sizing for Processes training course is designed to provide the harmony of theoretical knowledge behind pump basics and practical guidelines for its sizing procedure.During the industrial age, one of the first essential machines was invented. This machine is pumping system. Since then, it continues to evolve with different sizes, types, and application.Pump is a piece of mechanical equipment which moves the liquid from level to high level or moves fluid from the low-pressure area to high-pressure area. It can also be a booster in a piping network system. Moreover, it converts merely transfer liquid from source to destination and circulate fluid around a system. Reports show that pumping system has been the 20 percent of worlds electrical demand and the 25-55 percentage of energy usage in some industries.The training course goes over the following topics, in 16 lectures and 3 practice sessions with 1.5 hours of video training material:Why are Pumps Needed?Pumps General CharacterizationFactors Affecting Pump SelectionCentrifugal Pumps: Essential Components and Performance ParametersPump Head, Head CalculationsShutoff Head and Pump RunoutPump Power RequirementNet Positive Suction Head (NPSH) and Its CalculationPump Performance CurvePump Operational Issues and Possible CausesThe above essential topics have clearly been discussed during the course. This training can be really helpful for students, engineers, and even teachers aiming to deliver the essentials of oil and gas separation design from the engineering point of view. By spending only 1.5 hours, you can really understand the whole topic and further do practical calculations. The course instructor does also provide the service of answering questions for all course participants for free.

Overview

Section 1: Pump Unit Operation: Fundamentals

Lecture 1 Why are Pumps Needed?

Lecture 2 Pumps General Characterization

Lecture 3 Factors Affecting Pump Selection

Lecture 4 Centrifugal Pumps: Essential Components

Lecture 5 Centrifugal Pumps - Performance Essentials

Lecture 6 More on Pump Head

Section 2: Pump Unit Operation: Sizing Essentials for Processes

Lecture 7 Practice Session 1: Head Calculation - PART I

Lecture 8 Practice Session 1: Head Calculation - PART II

Lecture 9 Shutoff Head and Pump Runout

Lecture 10 Pump Power Requirement

Lecture 11 NPSH (Net Positive Suction Head)

Lecture 12 Practice Session 2: Determination of Cavitation Risk - PART I

Lecture 13 Practice Session 2: Determination of Cavitation Risk - PART II

Lecture 14 Pump Performance Curve

Lecture 15 Practice Session 3: Centrifugal Pump Design

Lecture 16 Pump Operational Issues and Possible Causes

Engineers working with Pumps,Process Engineers,Chemical Engineers,Chemical Process Engineering Graduates or Undergraduates,Any Discipline Engineers Aiming to Learn Essentials of Pump Unit Operation and Sizing

Homepage

https://www.udemy.com/course/pump-unit-operation-fundamentals-and-sizing-for-processes/Rapidgator

eidbx.Pump.Unit.Operation.Fundamentals.And.Sizing.For.Processes.rar.html

Uploadgig

eidbx.Pump.Unit.Operation.Fundamentals.And.Sizing.For.Processes.rar

NitroFlare

eidbx.Pump.Unit.Operation.Fundamentals.And.Sizing.For.Processes.rar

Fikper

eidbx.Pump.Unit.Operation.Fundamentals.And.Sizing.For.Processes.rar.html

Pump Unit Operation Fundamentals And Sizing For Processes Torrent Download , Pump Unit Operation Fundamentals And Sizing For Processes Watch Free Online , Pump Unit Operation Fundamentals And Sizing For Processes Download Online